Flexo® Halar

Low Outgassing, Self Extinguishing, UL-2024 Rated Sleeving

Flexo® Halar® self-extinguishing sleeving is used where flammability, high temperature endurance and low outgassing are primary concerns. Halar® is braided from 11 mil ethylene chlorotriflouroethylene (ECTFE) copolymer monofilament.Because of its low flame spread and smoke generation properties, this product meets UL 2024 and NFPA 262 plenum specifications, carries a UL flame resistance rating of VW-1 and exceeds automotive industry requirements of FMVSS 302, as well as aviation industry requirements of FAR 25. Halar® resists a wide range of corrosive chemicals and organic solvents, including strong acids, chlorine and aqueous caustics. Halar® ECTFE also maintains useful properties on exposure to cobalt 60 radiation at doses up to 200 megarads.

- Resists Common Chemicals & Solvents

- Expands Up to 150%

- UL-2024 & FAR 25 Approved

- Cuts Easily With Hot Knife

- RoHS Compliant

- Very Low Outgassing

- Operating Temp: -103°F to 302°F (-75°C to 150°C)

- Melt Temp: 482 ºF / 250 ºC

What Does ‘Flame Retardant’ Mean?

Flame retardant refers to a substance or material that is designed to resist or delay the ignition and spread of flames. Flame retardants work by interrupting the chemical reactions that occur when a material is exposed to heat or flames. They can prevent or slow down the release of flammable gases, reduce the amount of oxygen available for combustion, or create a protective layer that shields the material from the fire.

Flame Retardant Vs. Non-Flammable

Flame retardant: These materials are designed to resist flames and prevent or slow the spread of fire. These materials are treated with special chemicals that react to heat and flames, creating a barrier that can help protect against fire and reduce the risk of damage or injury.

Non-Flammable: These materials are those that do not burn or ignite at all, even when exposed to heat or flames. These materials may be made from special types of metals or other materials that have a very high melting point or are inherently resistant to fire.

We believe sleeving is the best of all worlds when it's time to deal with harnesses, snakes and bundles, and we want to convince you that some type of sleeving will be the perfect balance of economy, ease of use and long term usability for your applications. Unlike other products designed for cable management, expandable sleeving is quick and economical to install on applications of virtually any length. In addition, the reduced weight and volume of sleeving is negligible to the overall diameter and weight of the application. The visual appeal of braided sleeving is an important factor as well. Many companies and individuals the world over use Techflex® brand braided sleeving for their wires, tubes, cords, and more. For professional applications, home installations, and even arts and crafts projects, Techflex® braided sleeving is your best solution!

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

How To Cut Sleeving with a Hot Knife

To ensure a frayless, professional end on any installation, it is recommended that expandable braided sleeving be cut with a hot knife, rope cutter, or similar tool. We offer a wide variety of Hot Knives for different applications, including handheld knives, table knives, and replacement blades. Watch our video on Using A Hot Knife To Cut Braided Expandable Sleeving.

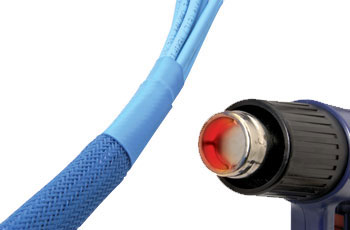

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.

How To Install Sleeving with the Speed Sleeve Tool

The Speed Sleeve Tool eliminates the mind-numbing process of applying expandable sleeving to a cable bundle. With the Flexo Sleeving Rapid Install Tool, the process is dramatically speeded up, considerably reducing labor costs. The system is simple to set up and interchangeable components accommodate diameters up to 2". Simply slide the desired length of sleeving over the properly sized pipe, and insert the desired wires or cables. The machine will quickly unravel the sleeving over the application and give it a smooth finish.

How To Organize with Spools & Displays

Spool and product management is now more efficient than ever. Our display/dispenser rack allows easy control of sleeving and provides a controlled system of dispensing directly from the spools. The spools drop into the slots and turn freely for dispensing. Full visibility ensures easy management of remaining inventory and simple drop-in replacement of empty spools. The spools themselves can be used with or without the display racks, allowing for customized storage and easy use of long lengths of braided sleeving.