ThermaShield® Tube

High Performance Thermal Protection

ThermaShield® Tube creates a buffer between your wires, hoses, cables, and high temperature environments. Engineered by laminating an aluminum heat shield to a layer of strong fiberglass insulation. This system provides superior protection from radiant heat by reflecting it away from sensitive electronics, wiring, and hoses. ThermaShield® Tube is designed to easily slip over wire or hoses. The seamless construction provides full coverage and protection. The flexible sleeving cuts with scissors and resists gasoline and engine chemicals. ThermaShield® Tube is ideal for protecting delicate electronic component boxes mounted close to engines or other heat sources.

- Economical & Easy to Install

- Reflects Radiant Heat

- Resists Gasoline and Engine Chemicals

- Operating Temps: -76°F to 392°F (-60°C to 200°C)

- Cuts Easily with Scissors

- Insulates Delicate Wires and Components

- RoHs Compliant

- Melt Temp: 2,048°F/1,120°C

About The ThermaShield® Family of Products

ThermaShield® creates a thermal buffer between your wires, hoses and cables and the high temperature environments surrounding them. ThermaShield® is engineered by laminating an aluminized metallic heat shield to a layer of strong, tightly braided fiberglass insulation. This system provides superior protection from radiant heat by reflecting it away from sensitive electronics, wiring and hoses.

ThermaShield® Convoluted – This pre-rounded sleeve, comes in 4 ft sticks, and is easy to slip over wires or hoses, and bend in any direction needed. The seamless construction provides full coverage and protection, and the flexible sleeving cuts easily with scissors.

ThermaShield® Tube – This tube is very flexible & will endure temperatures up to 1,200°F without delaminating, turning brittle or suffering adhesive failure. It is ideal in any situation where protection from radiant heat is a primary concern, and long length of flexible material are required.

ThermaShield® Wrap – When component disassembly isn’t an option, ThermaShield® Wrap is the solution. Designed to fit securely around existing assemblies and hard to reach components, the flat material is joined along the edge with a strip of permanent, high temperature adhesive. The aggressive bonding agent will securely adhere anywhere along the width of the material, affording maximum protection and allowing a snug fit around odd-shaped connectors and terminations.

ThermaShield® Flat – An aluminum laminated fiberglass sheet with a full coating of permanent, high temperature adhesive, applies directly to any clean surface. Ideal solution for protecting delicate electronic component boxes mounted close to engines or other heat sources. When applied, the aluminum laminate reflects heat away and the insulating fiberglass backing protects the fragile contents from thermal damage and failure.

ThermaShield® Tape – A high temperature and EMI/RDI shielding tape that exhibits outstanding heat reflectivity and thermal stability at extremely high temperatures for short periods of time. The tape is constructed of 1 mil aluminum foil, laminated on 2 mil glass cloth with silicone adhesive.

ThermaShield® Connector Shield – The Techflex® Connector Shield is specially designed to protect your connectors from all types of heat. Engine and exhaust temperatures on today’s motors can quickly exceed the design limits of plastic connector bodies.

T6 ThermaShield® - One of the most popular items in the ThermaShield® line of aluminized fiberglass products, T6, is designed for ease of installation when component disassembly isn’t practical. Just wrap the pre-formed, split flexible tube around any component and seal the sides with the high temperature adhesive strip to provide protection from hot pipes and engine components.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

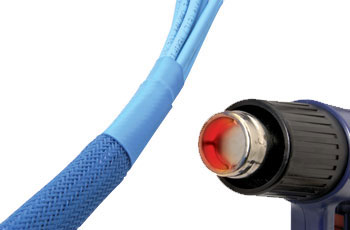

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.