Flexo® Silica Sleeve

Easy Slip On Installation & Protects up to 1,800°F

Densely woven Flexo® Silica Sleeve is ideal for protection of delicate components and personnel from exposure to high temperature exhausts and pipes. Flexo® Silica Sleeve is braided into a strong and flexible sleeve from silica yarns. The thick 60 mil walls of this sleeving provide enhanced thermal protection up to 1,800°F. This product cuts easily with scissors or shears and expands to allow easy installation over water cooling hoses, hydraulic hoses, and electrical cables. Also provides great insulation for exhaust systems.

- Cuts Easily With Scissors

- Easy to Install

- 60 Mil Wall Thickness Provides Enhanced Thermal Insulation

- Resists Common Chemicals & Solvents

- Maximum Continuous(Mil-I-23053) 1800°F./982°C.

- Extremely Abrasion and Cut Resistant

- High Temperature Resistance

- Ideal for high temperature exhaust and pipes

- Excellent Low Temp Flexibility

- Operating Temperature Range: Melt Temp(ASTM D-2117) 3000°F./1649°C.

Why Do I Need High Temperature Sleeving?

There are many applications where high temperature braided sleeving is essential, such as in aerospace, automotive, industrial, and military settings. In these environments, wires and cables may be subjected to intense heat from engines, exhaust systems, or other high-temperature sources. Without proper insulation and protection, these components can become damaged or even fail, leading to system downtime, safety hazards, and costly repairs.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

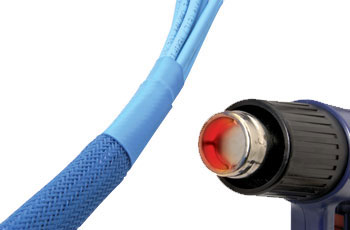

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.