FLEXO® TIGHT WEAVE™

Tighter Construction For Added Coverage & Protection

Flexo® Tight Weave™ is designed for use in applications where a balance between economy, optimum coverage, and abrasion resistance is required. The tightly braided construction increases the coverage, wear factor and improves security in any type of harness or cable bundle. Tight Weave™ provides substantially greater coverage and protection from abrasion than our standard Flexo® PET sleeving.

- Resists UV Damage

- Very High Abrasion Resistance

- Expands Up To 150%

- Operating Temps: -94°F to 257°F (-70°C to 125°C)

- Halogen Free - RoHS Compliant

- Resists Common Chemicals & Solvents

- FAR 25, FMVSS 302 Approved

- Melt Temp: 482°F/250°C

We believe sleeving is the best of all worlds when it's time to deal with harnesses, snakes and bundles, and we want to convince you that some type of sleeving will be the perfect balance of economy, ease of use and long term usability for your applications. Unlike other products designed for cable management, expandable sleeving is quick and economical to install on applications of virtually any length. In addition, the reduced weight and volume of sleeving is negligible to the overall diameter and weight of the application. The visual appeal of braided sleeving is an important factor as well. Many companies and individuals the world over use Techflex® brand braided sleeving for their wires, tubes, cords, and more. For professional applications, home installations, and even arts and crafts projects, Techflex® braided sleeving is your best solution!

What Makes Tight Weave® Different From Other Sleeving Products?

Flexo® Tight Weave™ is designed for use in applications where optimum coverage and abrasion resistance is required while flexibility & aesthetics are not compromised. The tight braid construction reduces show through and increases the coverage and wear protection.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

How To Cut Sleeving with a Hot Knife

To ensure a frayless, professional end on any installation, it is recommended that expandable braided sleeving be cut with a hot knife, rope cutter, or similar tool. We offer a wide variety of Hot Knives for different applications, including handheld knives, table knives, and replacement blades. Watch our video on Using A Hot Knife To Cut Braided Expandable Sleeving.

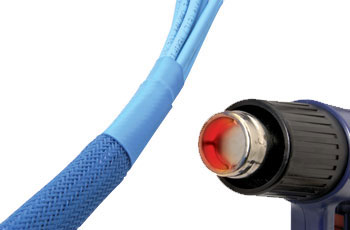

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.