FireFlex®

High Heat Protection

Silicone jacketed fiberglass sleeving is the choice of professionals in racing and other industries where protection from constant temperatures approaching 500°F is mandatory. FireFlex® fiberglass/silicone sleeving is engineered to protect hoses, cables and wire harnesses from damage due to exposure to extreme heat, open flame, molten splash and welding sparks. The thick, high temperature fiberglass sleeve is jacketed with a non-permeable, heavy silicone coating that is flexible enough to follow tight radius curves, resists all automotive chemicals and solvents, and provides a substantial level of abrasion and puncture protection. FireFlex® is completely non-conductive, will not melt, delaminate, become brittle or support combustion under normal conditions, and provides a professional level solution to thermal protection needs in any application.

- Cuts Easily With Scissors

- Will Not Burn or Support Combustion

- Extremely Abrasion and Cut Resistant

- Operating Temps: -65°F to 500°F (-54°C to 260°C)

- Asbestos Free - RoHS Compliant

- Resists Common Chemicals & Solvents

- Average 0.080" Wall Thickness

- Melt Temp: 2,048°F/1,120°C

About The FireFlex® Family of Braided Sleeving Products

FireFlex® products are completely non-conductive, will not melt, delaminate, become brittle or support combustion under normal conditions, and provides a professional level solution to thermal protection needs in any application.

FireFlex® - This silicone jacketed fiberglass sleeving is the choice of professionals in racing and other industries where protection from constant temperatures approaching 500°F is mandatory.

FireFlex® Aero – This sleeve is engineered from a dense braided fiberglass sleeve and a thick coating of self-extinguishing high temperature silicone rubber that withstands 500°F continuous exposure, and molten splash up to 2,000°F. FireFlex® Aero meets the specification of AS1072, allowing qualified hose assemblies to pass the fire resistance testing specification of AS1055D.

FireFlex® Snap Wrap – This wrap offers the same high temperature protection as traditional FireFlex® being constructed of silicone blanketed fiberglass. Heavy duty snaps dot the edges of Snap Wrap allowing quick and easy installation (or removal) that’s, um…well, a snap!

FireFlex® Wrap – This wrap protects and shields important hoses and cables from extreme heat and catastrophic flame outbreaks. Its unique hook and loop closure system allows for installation without the need to remove and reconnect fittings and terminations. The reusable closure additionally allows for easy repair, minimizing labor and costly downtime.

FireFlex® Flat - Fireflex® Flat provides the same protection against exposure to extreme heat, open flame, and molten splash as Fireflex® sleeve but in a versatile tape. It is specifically designed to protect components of irregular shape, such as hose splitter assemblies and cable splices. The heavy silicone coating maintains flexibility while resisting all automotive chemicals and solvents and providing an increased level of abrasion protection.

Tips for Installing & Terminating Braided Sleeving

How To Determine What Diameter Sleeving You Need

Bundle the cords that you’ll be covering and measure the diameter of the bundle. If you want a snug fit, choose a braided sleeving option with a slightly smaller diameter than that of your cables. If you want a loose and flexible fit, choose a braided sleeving option with a diameter that is equal to or slightly larger than that of your cables. Keep in mind that braided sleeving loses 2% to 3% of its length when it expands. Be sure to plan accordingly!

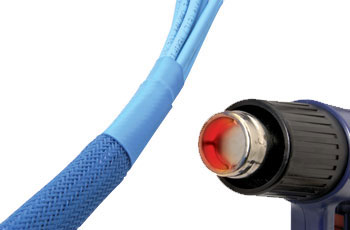

How To Terminate Sleeving with Heatshrink Tubing

Heatshrink Tubing is the ideal way to create a tight, professional finish on any wire, hose or cable management project. Once shrunk, the tubing will hold its reduced state, even at elevated temperatures. This application can be used to protect, color code, brand, or secure ends or sections of braided sleeving. A Heat Gun is required to properly apply heatshrink tubing. You can find a guide to the proper technique for working with heatshrink tubing Here.